The last LIFE project was started in September 2015 with the collaboration of SACME and University of Padova: the aim of LIFE M&M Man and Metal is to develop an innovative business model to obtain truly eco-compatible metal wire.

The project foresees three phases:

- the preparation of the protective new alloys or pseudo-alloys using only recycled metals, such as aluminum shavings and scraps and zinc gross;

- the development of a thermal spray system able to deposit a thin, controlled and dense layer of protective new alloys on the surface of the wire;

- the mechanical treatment to densify the deposited layer through shot blasting.

THE LIFE PROGRAMME

The LIFE programme is the European Union’s financial instrument for the environment and climate action. The general objective of LIFE is to contribute to the implementation, updating and development of European environmental and climate policy legislation, by co-financing projects with European added value.

LIFE was founded in 1992 and, to date, has already completed four phases of the programme (LIFE I, LIFE II, LIFE III, LIFE+). During this period, LIFE has co-financed 3,954 projects within the EU, contributing about € 3.1 billion to the protection of the environment.

The European Commission (and DG Climate Action) manages the LIFE programme. The Commission has delegated the implementation of many components of the LIFE programme to the Executive Agency for Small and Medium-sized Enterprises (EASME). External selection, monitoring and communication teams provide assistance to the Commission and EASME.

The new LIFE programme has been adopted with the LIFE 2014-2020 Regulation (EC) No 1293/2013. The budget for the period is set at €3.4 billion in current prices. The LIFE programme will contribute to sustainable development and to the achievement of the objectives and targets of the Europe 2020 Strategy, the 7th Union Environmental Action Programme and other relevant EU environment and climate strategies and plans.

The ‘Environment’ strand of the new programme covers three priority areas: environment and resource efficiency; nature and biodiversity; and environmental governance and information. The ‘Climate Action’ strand covers climate change mitigation; climate change adaptation; and climate governance and information.

The programme also consists of a new category of projects, jointly funded integrated projects, which will operate on a large territorial scale.

Info: Life Progamme

BACKGROUND AND OBJECTIVES

One of the most popular and effective protection of the wire is the galvanic coating or galvanizing. The wire should be subjected to degreasing, pickling, fluxing and preheating to 100°C, before being immersed in a bath of molten zinc at 455°C.

This system has a strong environmental impact, such as a large consumption of zinc (raw material which is rapidly being exhausted) and a high CO2 production. The aim of the project is to develop an innovative business model to obtain truly eco-compatible metal wire, in which traditional hot-dip galvanising is replaced by the controlled application of light protective metals (aluminum and zinc alloys containing a high percentage of aluminum, using sources of recycled metals) in a reduced thickness, to achieve extremely durable and fully recyclable products.

THE LIFE M&M PROJECT

The LIFE M&M Man and Metal project is a part of the revolutionary process of Cavatorta Group to modify every pollutant aspect of its companies to convert this kind of processes into sustainable techniques: Metallurgica Abruzzese in fact has already presented other positively concluded Life Projects of which this is complementary to consolidate and complete the process. Even if it seems to have a similar purpose, its application is complementary inside the production cycle and dedicated to different products.

The project is based on a new steel wire protection system for the production of an innovative range of products characterized by a greatly reduced use of zinc and maximum corrosion resistance, thanks to the thin layer of coating with protective elements such as aluminum and zinc alloys containing a high percentage of aluminum (quasi-alloys).

DEVELOPMENT ACTIONS

The project foresees four phases, whose synergy will bring undoubted environmental and technological benefits:

- ALLOY: development of Al-Zn alloys and pseudo-alloys with a high Al content for the protection of low carbon steels, using sources of recycled Zn and Al (such as aluminium shavings and zinc dross); preparation of powders for thermal spraying and recycling of the overspray collected in the deposition phase to create the new alloys.

- COATING: study, design and development of the multi-nozzle wire thermal spray system, able to ensure the homogeneous coating of rapidly moving carbon steel wire and the recovery of the overspray; installation of the deposition system and operating tests with alloy and Al-Zn pseudo-alloy powders.

- DENSIFICATION: study and design of a coated wire shot blasting system for thermal spraying, with the aim of increasing its surface density guaranteeing the almost complete absence of porosity that usually occurs with typical light alloy thermal spray processes.

- DEMONSTRATION: production of products protected by the new alloys (wires, mesh) and their characterization in comparison with the normal production of galvanised products; definition of recycling methods and LCA of the new material.

EXPECTED RESULTS

The main benefits deriving from the proposed innovation are of an environmental, technical and economic nature:

- Reduction in the use of Zn, which is rapidly being exhausted, by up to 90% in the protective alloy.

- Reduction in the thickness of the protective coating by over 40%, resulting in savings in raw materials.

- Development of protective alloys and pseudo-alloys using recovered metals, some recovered internally (galvanising dross) and others from nearby companies (Al alloy shavings).

- Reduction of embodied energy and of CO2 production by 20% compared to normal galvanised wire.

- Increase in the useful life of the products, estimated at 250% compared to normal hot dip galvanising (corrosion rate is reduced by 250%) in rural environments; increase of up to 800% in industrial environments, with the same thickness.

- Elimination of the formation of intermetallic compounds and ease of recovery of the alloy or psuedoalloy deposited or deriving from the overspray.

- Improved ductility of the coated wire, without hard and fragile intermetallic compounds.

- Improved surface finish and appearance of the protected surface.

DEVELOPMENT OF THE PROJECT

The project regularly started on September 2015. First the management and monitoring actions were planned, involving the partner University of Padova, who have been allowing the project to run smoothly, as according to the times, objectives and expected costs.

From the technical point of view, the project started with a first phase concerning the ALLOY action. The main aim of this action is to identify the possible alloys or pseudo-alloys to be used during the thermal spraying phase and which is able to provide the metal wire with excellent protection against corrosion.

The action was divided into four different sub-actions:

- 1.1 – selection of Al-Zn alloys and pseudo-alloys for protective steel coating

- 1.2 – identification and procurement of recycled metals that can be used for the production, by means of a thermal process, of the alloys and psuedo-alloys

- 1.3 – production tests of thermal spraying powders using the pseudo-alloys identified: sieving, milling and spheroidization

- 1.4 – characterisation of the powders obtained

With the first two sub-actions identified the materials to be used to coat the metal wire by thermal spraying, in order to ensure protection against corrosion that is at least as great as (if not greater than) that obtainable with traditional hot galvanising, and identified the relative suppliers of the materials.

After thorough analysis of the materials that can be used, it was decided to use a series of waste metals (from both internal and non-internal processing) in order to obtain different types of product to be used in different environments:

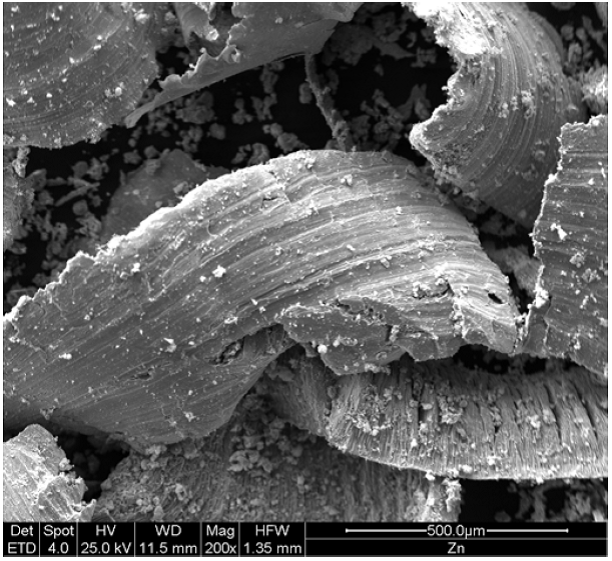

- Zinc, obtained mainly from waste (zinc mattes) from hot galvanisation. It was decided to use the waste produced inside Metallurgica Abruzzese during the phase of hot galvanising of the wire, because on the one hand the quality of and the consistency of the characteristics of the zinc matte produced would not be in doubt (because there would be no need to obtain new supplies each time from different manufacturers with different productive cycles and systems that made the composition of the incoming product different) and on the other hand the environmental impact of procurement would be reduced, in particular the production of CO2 during the transport phase.

- Aluminium, which may also be obtained from processing waste, rather than from the traditional recycling cycle, because in this way it is possible to control the quality of incoming metals more effectively. A couple of main suppliers have been identified.

- Zinc-aluminium alloy (normally known by the commercial name Galfan®), normally consisting of 95% zinc and 5% aluminium. Also in this case, as for zinc, mainly internal manufacturing waste will be used.

After the materials identified above were procured, the experimental phase commenced for the production of powders for thermal spraying coming from metal waste.

As the companies involved in the project did not have great expertise in this field because they were more than anything users of the product, an outside company (K4Sint) was used, as envisaged in the project. Ties with K4Sint were forged through networking activity. Owing to their experience and expertise, it was possible to obtain powders directly from waste in special mills.

In view of the results obtained, Metallurgica Abruzzese has decided to use a mill for metals and the powders obtained have been sent to the University of Modena and Reggio Emilia (outside project consultant) for the characterization.

As said, the powders obtained from the milling phase were sent to the “Enzo Ferrari” Department of Engineering of the University of Modena and Reggio Emilia (outside project consultant).

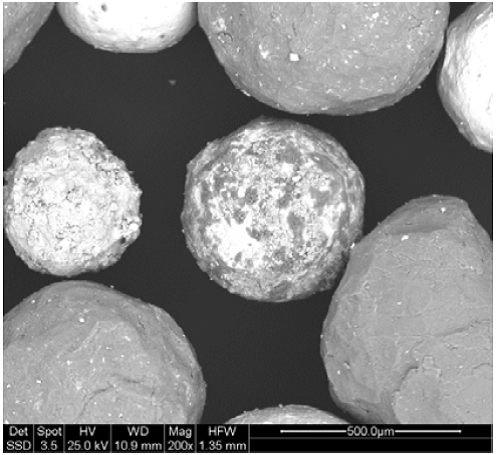

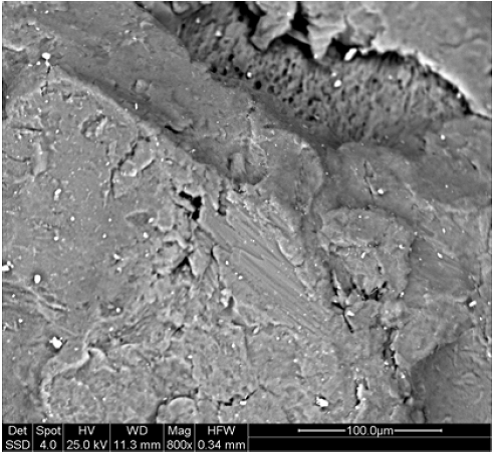

The first results of the analyses show oxidation of the aluminium balls that consist of 92% Al and about 7% O and of the zinc balls that consist of 56% Zn and 42% O.

Zinc chips were also characterised that derive from other manufacturing cycles to establish whether they can be used in the manufacture of zinc powders: however, the latter, in addition to the expected oxidation, had a high iron content.

Lastly, aluminium powders of commercial type were analysed, in which there was no contamination and the level of oxidation was almost zero.

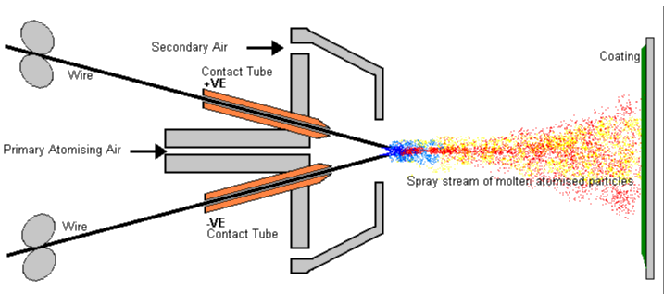

Nevertheless, the type of thermal spraying identified, the “Electric-arc wire”, does not require metal powders, but metal (zinc or aluminium or Zn-Al alloys) wires, therefore it became necessary, instead, to identify, investigate, realise and test a new system for recovering the recycled material (zinc, aluminium or Zn-Al alloys) as well as preparing the wire needed for feeding the thermal spray system.

By means of a prototypal rotating drum, obtained and tested, it is possible to separate the metal (Zn or Zn-Al alloy) from the Fe-Zn alloy (in the case of zinc mattes), from the Fe-Zn-Al alloy (in the case of Galfan® mattes), or from an ensemble comprised of vermiculite and oxides and zinc oxychlorides (in the case of zinc ashes and Galfan®); in this way, zinc or Zn-Al alloy billets and ingots are obtained. Results confirm that 70% of waste by weight can be recovered that would otherwise be disposed of. Likewise, it is possible to obtain aluminium billets from aluminium scraps and shavings).

Billets and ingots have been supplied by an outsourced company in charge of transforming said materials in wire rods and returning them to Metallurgica Abruzzese, where they undergo the next processing phase.

The Zn (or Al or Zn-Al) wire rod undergoes a drawing cycle to reduce its diameter until a zinc wire (or Zn-Al wire) is obtained; the same is to be used for feeding the electric-arc wire system during the thermo spraying phase.

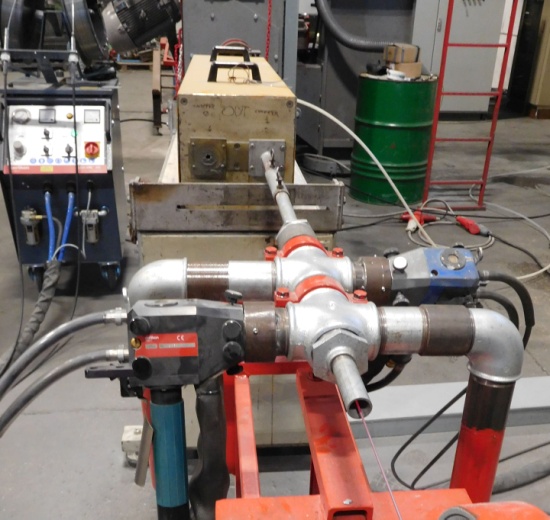

The project goes ahead with the COATING action.

The main purpose of this action is to fine-tune the thermal spraying technology, which is capable of ensuring an optimal protective coating for the metal wire when in transit.

The action was divided into four different sub-actions:

- 2.1: development of thermal spray system to spray Al-Zn alloys and psuedo-alloys on a filiform substrate

- 2.2: definition of the optimal thermal spraying parameters to minimise the overspray and guarantee the homogeneous coating of the wire

- 2.3: production tests of wire coated with the identified pseudo-alloys and characterisation of the product

- 2.4: design and development of the overspray recovery system for internal recycling

Metallurgica Abruzzese undertake networking activities with a beneficiary of another LIFE project, its core-business being thermal spraying activities.

Thanks to the availability of the company, thus the first tests of thermal spray have been initiated, although with only one nozzle: the results were encouraging, even though they are not regarded as sufficient to allow replication of the technology.

The technology used (Air Plasma Spray), in fact, is not suitable for the needs of the demonstration project, as well as subsequent replicability and transferability, especially related to the economic aspect.

All the different thermal spray techniques have been taken into account: in fact fall under this name different thermal deposition techniques, which differ by the different way of administering thermal energy to the particles by spraying. These different techniques can be enclosed in three categories:

- Plasma spraying

- Combustion Spraying

- Electric Wire-Arc

After careful analysis, it was decided for the adoption of Electric Wire-Arc technology, which also has the advantage of being the most economic technology.

It is also possible to use both zinc wires, aluminium wires and zinc-aluminium alloys wires as conductors wires, thereby allowing the deposition of zinc, aluminium or zinc-aluminium alloys. By adjusting the thickness of the wires or by varying the wire feed speed, the percentage of the mixture can also be varied.

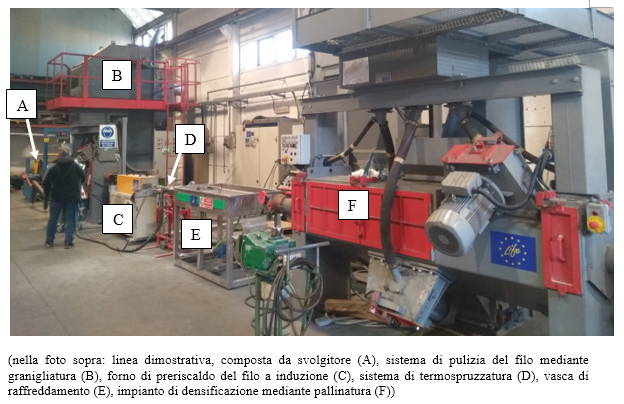

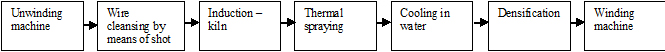

The tests had not produced the desired results. Therefore, we decided to reconsider the demonstration line by introducing a pre-heating phase for the wire prior to the thermal spraying phase, using an induction kiln.

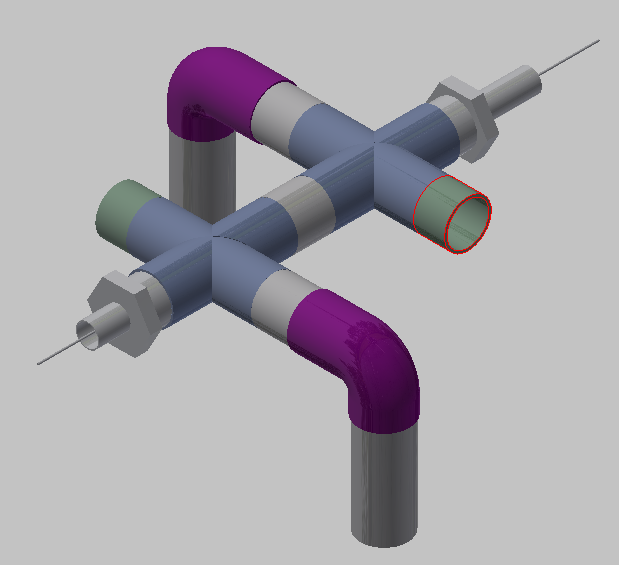

The new composition of the demonstration line is shown in the diagram below:

Thanks to the adoption of the pre-heating phase, we saw great improvements since the beginning in the adhesiveness of the zinc coating applied by thermal spraying to the wire in transit.

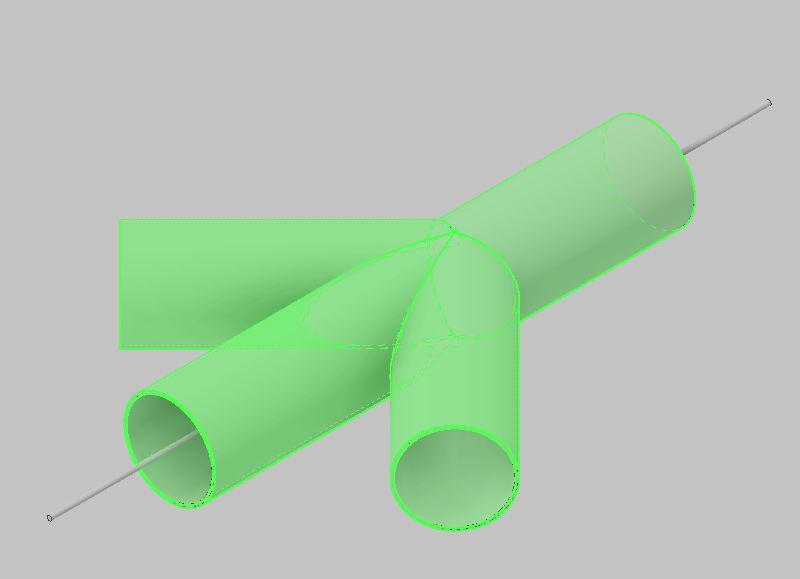

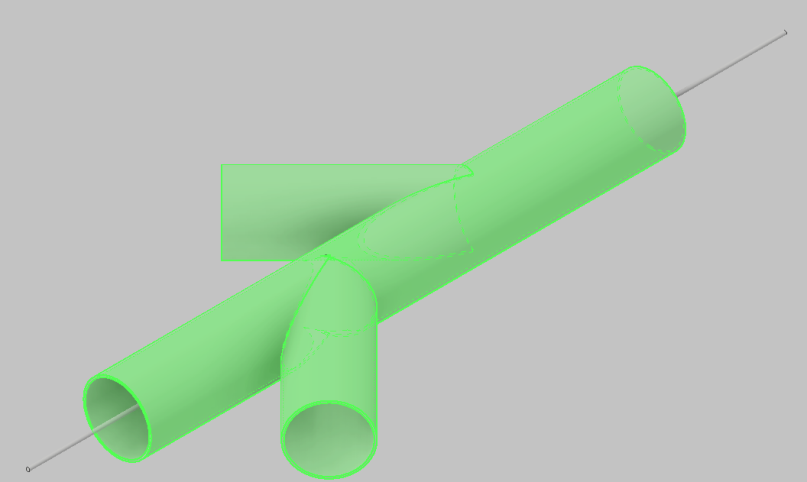

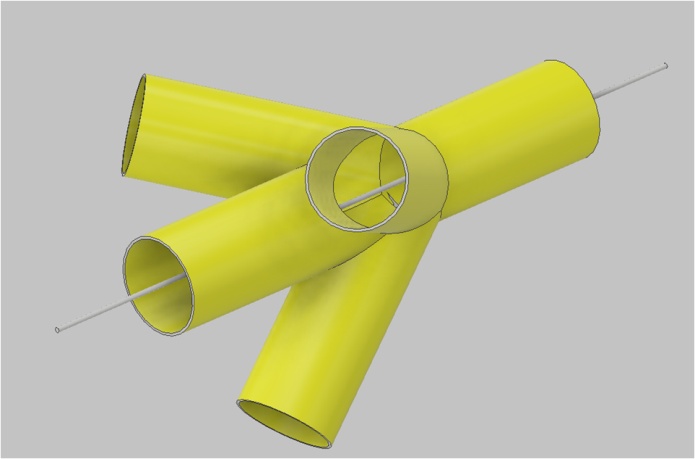

In the light of the results of the first tests, we focused on the simulation study for identifying the best thermal spray system conformation, in particular, the positioning of the spray guns.

Finally, we opted for the solution entailing two guns with orthogonal opposed spraying angles: the line has been realised and tested with optimal results.

The project goes ahead with the POST TREATMENT (or DENSIFICATION) action, with the aim of increasing the surface density of the coated wire.

The action was divided into three different sub-actions:

- 3.1: sizing of the micro shot blasting system for the densification of the deposited layer

- 3.2: definition of the optimal shot blasting parameters to minimize surface porosity

- 3.3: production trials of coated and shot blasted wire

Since only a mild consolidation of the zinc -coated wire was required for the purpose of the project, to avoid the peel off of part of the coating the micro shot blasting system was adjusted to run at low power and the spheres have been replaced with zinc particles, since zinc is known to be softer than the conventional steel and ceramic spheres.

The last technical action of the project is the DEMONSTRATION action, to realise WIRE AND NETS.

This action was divided into three sub-actions:

- 4.1: installation on line of the thermal spray and shot blasting demonstration systems for the production of wire coated with the new Al-Zn alloys or pseudo-alloys

- 4.2: definition of welding parameters to obtain protected electrowelded mesh and panels

- 4.3: production tests of wires and mesh, characterisation of mechanical properties and corrosion resistance

The main objective of this action was to carry out production tests on the wires, coated with Zn-Al alloys or pseudo-alloys, produced using the new thermal spraying system, and subsequently produce electro-welded meshes and panels using the wires obtained.

From a technical perspective, the activity can be deemed virtually finished, as the welding tests run on the wire (used to produce the meshes and panels) has delivered excellent results.

The corrosion tests run on the wires and meshes made by thermal sprayed zinc and/or aluminium, carried out by the University of Modena and Reggio Emilia, are complete and have confirmed the competitiveness of the new products with respect to conventional galvanised wires and meshes.

Moreover, several samples of wire and meshes have been produced, which are supplied to select customers for the stage consisting of the field test under real conditions.

In addition to technical activities, another important action is the ENVIRONMENTAL AND SOCIO-ECONOMIC MONITORING of the project, carried out by the University of Padova, partner of the project: aim of this action is to monitor the impacts and sustainability of the project on the environmental problem targeted.

The activity, as well as LCA analysis, confirmed the benefits of the project.

DISSEMINATION OF THE RESULTS

Notice boards

Two types of notice boards were created bearing the Life logo, project references, and a brief description of the objectives to achieve. The notice boards were positioned in strategic points, with a high visibility, in Metallurgica Abruzzese and SACME.

Brochures

A bilingual brochure was created and distributed. It’s also downloadable at this link: Life M&M Man and Metal.

Layman’s report

A bilingual Layman’s report was created and distributed. It’s also downloadable at this link: Layman’s Report

Events

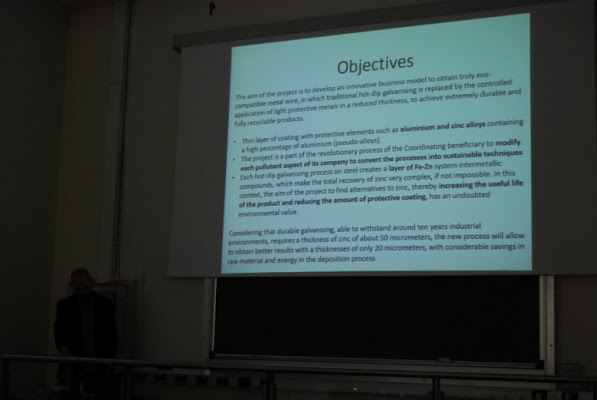

On May 28th, 2016 we took part in a day-long event called, “Welcome to the LIFE Programme”, organized by UNIPD in its Department of Industrial Engineering, within the framework of the Master in Environmental Management (see photo below). The day was structured in two parts: the first part was dedicated to the presentation of the LIFE program and several LIFE projects (including LIFE M&M project), and the second part was dedicated to a networking session for the beneficiaries of the LIFE projects participating in the event.

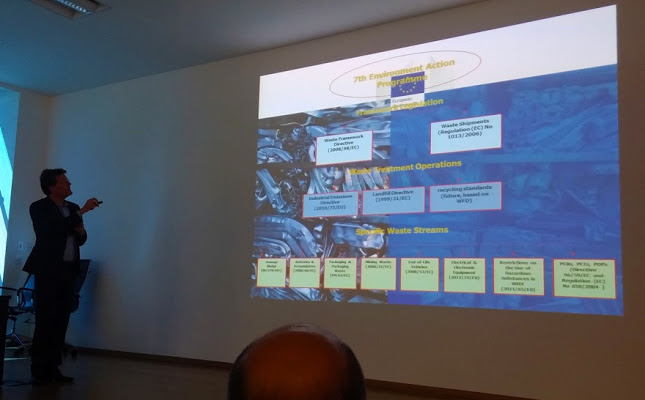

On 27th and 28th June, 2016 we took part in a two days-long event called “Platform Meeting on Circular Economy and Waste: Reducing waste generation from industrial sources and/or reducing hazardousness of industrial waste” held in Milano (Italy). It was a good opportunity to distribute our dissemination material (see photo below) and for networking activities.

On 27th May, 2017 we took part in a day-long event organised by UNIPD on occasion of the 25th Anniversary of LIFE at the Department of Industriali Engineering, with a brief presentation of the LIFE M& project and networking activities.

A few days later, on 09th June, 2017, we organized an event at Metallurgica Abruzzese headquarters in Mosciano Sant’Angelo on the occasion of the 25th anniversary of LIFE; the event was attended by representatives of the industrial world and local politicians. During the event we presented also the LIFE M&M Project. The conference was filmed and shown, both in full and in reduced version, on several local television stations, broadcast on digital terrestrial in the Abruzzo and Marche regions.

On 26th May 2018 we took part at the event “Welcome to the LIFE Programme”, organised by the University of Padova, with the presentation of the LIFE M&M project and networking activities.

On 21st June 2019 we organised the final event of the LIFE M&M Project, which was attended by representatives of local politics and trade associations. During the event, several LIFE beneficiaries presented their projects and results. The event was filmed and show on several local television stations, in the Abruzzo and Marche regions.

Fairs

Cavatorta Group participated in the following trade fairs, during which dissemination material of the project was distributed:

- Düsseldorf Fair (Germany, April 2018)

- Fieragricola Verona (January-February 2018)

- BakuBuild (Azerbaijan, October 2018)

Publications

To date, the following publications have been made:

- Cityrumors, 7th March 2019

- Tecnologie del filo

- Wire-Tech-World

- Edilportale (February 2020)

Other dissemination activities

- In April 2016, LIFE M&M Project has been mentioned in the newsletter of the Associazione Rete Italiana LCA, a network launched by ENEA (Italian National Agency for New Technologies, Energy and Sustainable Economic Development) in 2006 to encourage the exchange of information, methodologies and best practices.

- In March 2018, a company visit was organized with the main customers of the Puglia region, during which the benefits obtainable with the LIFE M&M project and the environmental commitment of the European Union with the LIFE programme was presented.

- In May 2019 we organised a meeting and a guided tour of the LIFE plant with the students of the “Marie Curie” school of Giulianova (TE)