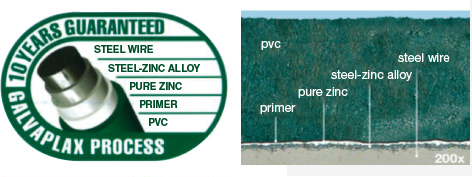

The Galvaplax® Process guarantees exceptional protection of the base wire thanks to the combination of galvanisation, primer and PVC. The operation starts with the galvanisation of the wire, it is then coated with a special primer which ensures absolute adherence of the PVC when it is passed through the fluid bed. Every product treated with this process is guaranteed to be corrosion free for 10 years.

The Galvaplax® Process is the exclusive pvc coating process by sintering, developed by Cavatorta to give the base wire or the galvanized wire mesh characteristics of durability and corrosion resistance. The wire or the mesh is galvanized, immersed in a bath of special primer that allows PVC powders, when melted at an elevated temperature, adhere perfectly to the metal and form a compact and homogeneous coating. Therefore, the sintering process allows an intimate and solid bond between the metal surface of the wire or the mesh and the PVC, while, at the same time, enhancing the aesthetic properties of the coating such as uniformity and brightness.

The PVC powders used in the Galvaplax® Process do not contain heavy metals such as cadmium and lead, whose presence would be dangerous for the workers, for those who store the product, for those who install and for the consumer.

Under normal operating conditions, the performance of wires plastic-coated with the Galvaplax Process are guaranteed for over 10 years against corrosion.