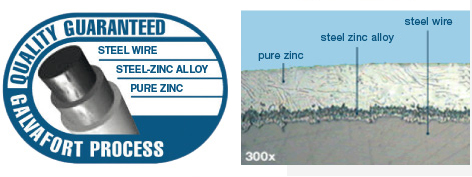

The Galvafort® Process is a heavy galvanising process developed by Cavatorta. The zinc layer is heavier than the minimum required by European Regulations and has an ultra smooth and uniform coating along the wire. The main advantage with material coated in this way is that the coating never cracks even when bent 180°. Every product treated with this process is guaranteed to be corrosion free for 10 years.

Galvafort Process is an exclusive and strong hot dip galvanizing process, of the wire or netting, perfected in the Cavatorta laboratories.

It provides an exceptional corrosion resistance that determines the high quality of Cavatorta products and which is due in particular to:

- A homogeneous, uniform zinc coating, on every part of the wire or the netting;

- A zinc coating in excess of the minimum required by European standards;

- A perfect adhesion of the zinc coating, which allows the wire or the netting not to crack when subjected to the bending test prescribed by product standard.

Galvafort Process is the best guarantee of the final product’s durability. The products galvanized with the highly technological Galvafort Process can withstand natural and normal climatic stresses in rural areas for a period exceeding 20 years.